Verilogic Solutions enables automation for businesses of all sizes.

Streamline and simplify advanced automation with the RIGHT solution. Our expertise includes, but is not limited to the following:

Collaborative Robots

- Collaborative Robots, or Cobots, are robots that can directly and safely interact with humans in a shared workspace. Cobots can be conveniently placed anywhere and relocated whenever needed as they can be re-programmed and re-deployed for different tasks. Cobots don’t replace people; they make employees more valuable by migrating tedious and repetitive tasks to Cobots which allows the employee to perform higher-value work.

- Cobots are typically used for pick and place, palletizing, quality inspection, and machine tending.

Cartesian Robots

- Cartesian robots, which are also called linear robots or gantry robots, are industrial robots that work on three linear axes (X, Y and Z). Cartesian robots are a popular choice as the modular design gives users the ability to adjust the robot’s speed, precision, stroke length, and size.

- Cartesian Robots are one of the most used robot types for industrial applications and are often used for CNC machines and 3D printing.

SCARA Robots

- SCARA is an acronym that stands for Selective Compliance Assembly Robot Arm or Selective Compliance Articulated Robot Arm. SCARA Robots function on 3-axis (X, Y, and Z), and have a rotary motion as well. SCARA Robots excel where high speed and high accuracy applications are required. SCARA robots are comparable to a Cartesian robot, but SCARA robots can move quicker and are the easiest to integrate.

- Typically, SCARA robots are used for material handling such as assembly, palletizing or pick-and-place applications.

Delta Robots

- Delta Robots, or parallel/spider robots, possess three arms connected to a single base, which is mounted above the workspace.

- Delta Robots are designed for low payload applications including packaging, assembly, and pick and place.

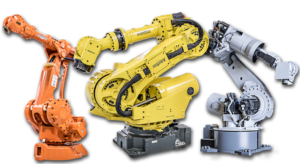

Articulated Robots

- Articulated robots mechanical movement and configuration closely resemble a human arm. One of the main benefits of six-axis robots is their expanded range of motion. Each axis of an articulated robot provides a degree of freedom, or in other words, an independent motion. The more axes on these robots allow for access to greater amounts of space, resulting in a larger work envelope than robots with fewer axes.

- Articulated robots can take over complex processes including inspection, mixed bin picking, machining, and welding with more accuracy, precision, and efficiency than humans.